When does a PLC system need replacement?

At eReM’s software department we regularly get the question to replace outdated systems. The most frequent questions are about the migration of Siemens Step 5 to Siemens Step 7. This is the reason why we decided to write a blog about the necessity of this type of migration. Which advantages does S7 bring? What is the method for migration? Finally, what are the possible migration strategies?

Siemens Step 5: an outdated system

In general, we say: never replace a system that works well. A lot of companies find it risky to migrate a system, because the costs can be very high. However, Siemens S5 is over 30 years old and is no longer supported. That is why migration is inevitable in many cases. Other reasons for migration are:

- It gets harder and harder to find qualified service and maintenance staff.

- Partly as a result, the maintenance budgets get higher every year.

- Because of the fact that S5 is no longer supported, there is a lot of work in maintenance and repairs.

- In some cases S5 does no longer meet the production capacity and product quality that companies try to achieve.

Advantages of Siemens Step 7

Adding modern functions is necessary in order to keep up with the competition. Besides, migrating to Siemens S7 is inevitable at some point, because old components can get broken and may lead to production loss. S7 can result in the following advantages:

- The system is better in line with new standards and guidelines in the industry, like safety and IEC standards.

- S7 has better and more extended options for the automation process.

- It is possible to integrate database and management systems (MES or ERP). Also HMI visualizations and technological functions like motion control and PID control can be added.

- It is possible to extend the system with communication modules like Profinet.

- S7 is a state-of-the-art platform that will be extended and supported the coming years.

- Also, S7 is less error-prone and will therefore cause an enhancement of the productivity in general.

Method for migration

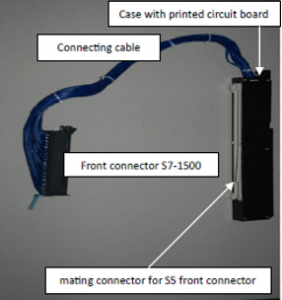

At first, the new hardware for the Siemens Step 7 system will be chosen. This also includes all components and communication packages. The wiring of the I/O cards can be transferred from S5 to S7 manually. However, it is also possible to use interface module adapters. These adapters help to reduce mistakes and save a lot of time.

Next, the software will be transferred with a migration tool. In most cases, a great part of the software can be translated with this tool. However, a certain part will always be transferred manually to enhance the readability. Some options in S7 will not automatically be filled out, therefore, a software engineer always needs to write new functionality. After this, an extended test protocol will be followed before the new software can be completed. All steps of the migration of the hardware and software are explained in a migration plan.

Migration strategies

It is best to migrate a system at once, but for some companies the costs are too high or there is a fear for messing with the existing software. Therefore, the choice can be made to migrate only a part of the system or to do it step by step. There is a distinction between the following migration strategies:

- System extension of S5 with S7: for example, an upgrade of the HMI/visualization part takes place, I/O points will be added or the communication network is being extended.

- Partial or gradual migration of S5 with S7: some CPU’s will be replaced for S7 or, for example, the field instrumentation is adjusted (frequency inverters, sensors, flowmeters etc.).

- Entire migration to S7: the complete control system will be designed again and transferred to TIA Portal (Totally Integrated Automation). Also, a connection can be made with information systems like MES or ERP.

Do you have questions as a result of this blog and/or do you want to migrate a system? Contact us now!