Our engineering manager John Meijer shares his knowledge. Every month he discusses a different topic in the field of electrical safety. This time his blog is about: Mandatory energy management according to the new NEN1010 part 8, for whom?

Our engineering manager John Meijer shares his knowledge. Every month he discusses a different topic in the field of electrical safety. This time his blog is about: Mandatory energy management according to the new NEN1010 part 8, for whom?

The background of part 8

Nowadays everything revolves around energy saving, efficiency improvement and sustainable power generation. Therefore, it come as no surprise that this is an important theme in the new NEN 1010:2020. The NEN 1010-8:2021: Functional aspects has recently been published, better known as ‘Part 8’. Part 8 is part of the new NEN 1010:2020, but will be published separately. It is expected that this section will be updated on a regular basis.

The objective of part 8 is in particular the efficiency of energy consumption. Three topics are discussed: Energy efficiency, low voltage electrical installation of prosumers* and the operation of electrical installations of prosumers, especially in the field of mutual communication.

*Prosumers: person who is producer and consumer at the same time.

Part 8 of the NEN1010 was mainly an advice in previous publications, but with the current requirements in the field of energy, its application has become an obligation. Therefore, this blog discusses an obligation from part 8: the Electric Energy Management System (EEMS).

The NEN recently held a webinar in which they explained the most important changes. This has been used as an information source for this blog.

Electrical Energy Management System (EEMS)

You can see the Electrical Energy Management System as a tool for building installations, but also for monitoring their use. This way you can notice early on that a part of an installation is no longer working properly, which can lead to energy loss. The EEMS helps to monitor the quality of the energy network.

The purpose of the EEMS is to provide insight into and control the actual performance by monitoring important parameters, such as outside temperature, occupancy rate, operating hours, etc. You need to determine which parameters are critical for management and performance monitoring to monitor changes in the consumer pattern.

The requirements and recommendations from part 8 may not affect the standard requirements of NEN1010, such as the safety of the installation and the availability of the installation. The NEN1010 is leading and provides the possibility to circumvent settings of the EEMS in deviating circumstances that lead to different energy consumption, such as overtime, illness, etc.

Which key numbers are we talking about?

The Electrical Energy Management System is required for:

- Buildings with a capacity of more than 250 people, or;

- An energy consumption of more than 100,000 kWh/year.

The EEMS based on an energy consumption of 100,000 kWh/year may sound like a distant reality, but you can already achieve 100,000 kWh/year with a continuous current of 3 times 16.5A on an annual basis (8760 hours). This is certainly not unusual, so the EEMS will be mandatory for many buildings.

The guidelines for EEMS

It is too extensive to go into detail in part 8 in this blog, but what should you generally take into account within the EEMS?

- The lowest energy consumption;

- Reducing electrical losses;

- The most favorable price through real-time adjustments in purchasing, storage and use;

- Efficiency control during the entire service life of the electrical installation (ISO 50001);

- New and existing installations and renovations to achieve higher energy efficiency.

1. The lowest energy consumption

All the decisions you make in the design process affect the lowest energy consumption. For example, do you opt for manual equipment within an installation or do you opt for sensors that switch lighting on and off automatically? In your design, you ideally opt for installations with an energy label A or higher. And don’t forget to take into account which equipment you purchase, especially the efficiency of the motors is important.

2. Reducing electrical losses

When designing the installation, make sure that the electrical losses are as low as possible. Please take into account:

- The load profile (per hour for a week);

- The optimal position of the transformer;

- The location of the high/low voltage substation;

- The operating point and efficiency of the mains transformer;

- The efficiency of local production and storage;

- The occurring pipe losses (busbars and cables);

- The power factor and the influence of harmonic currents (reactive power).

For example, for lower energy losses, it is better to place the transformer and distributor as close as possible to the largest consumer. The efficiency of a transformer is usually best between 30% and 50% of the rated load. Therefore, a slightly larger transformer can pay for itself within a few years, given the fact that a transformer lasts 25 years on average. The methods for determining the energy efficiency of transformers can be found in IEC/TS 60076-20:2017.

3. The most favorable price through real-time adjustments in purchasing, storage and use

It is important to always keep an eye on energy rates. Check with other suppliers regularly to see what the market is doing and whether you are paying a good price. As with all suppliers, it pays to look around and monitor your energy purchase costs.

4. Efficiency control during the entire service life of the electrical installation (ISO 50001)

Energy management according to ISO 50001 gives substance to the structural improvement of energy consumption and thus to cost savings. In recent years, many mechanisms have been developed to implement measures and provide insight into savings.

Energy management according to ISO 50001 gives substance to the structural improvement of energy consumption and thus to cost savings. In recent years, many mechanisms have been developed to implement measures and provide insight into savings.

An international standard has been drawn up for the EEMS, this standard has been published by NEN as NEN-EN-ISO 50001:2018 (English or Dutch). The standard describes the requirements that an energy management system must meet. The standard supports all types of organizations with the implementation of systems and processes to improve energy efficiency.

Part of ISO 50001 is the High Level Structure (HLS), the basic structure with core requirements for management system standards. This unambiguous structure facilitates the integration of ISO management systems.

5. New and existing installations and renovations to achieve higher energy efficiency

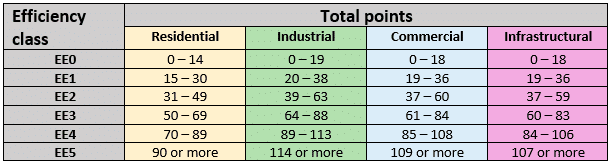

The energy efficiency of an electrical installation is indicated from low to high with EE0-EE5. The method is for new and existing installations for industrial, commercial, infrastructural and residential applications. The efficiency class of the installation is determined by adding points for specific parameters. If a parameter is not evaluated, it is given the value 0. The higher the value, the higher the efficiency.

Where and when do you purchase the standard?

In view of the many changes that have been made, it is strongly recommended to purchase part 8 (only available in Dutch) in addition to the new NEN1010:2020 (Dutch implementation of the HD-IEC 60364 series) or to take out a subscription online with NEN Connect. The standard is especially suitable for organizations that:

- Want to systematically improve energy management;

- Have to set up, implement, improve and/or maintain an energy management system;

- Want to ensure that the energy management is in order in accordance with the latest insights;

- Want to assess and evaluate their energy management against the standard;

- Want to make their energy management demonstrable to customers and third parties.

If you any questions after reading this blog, please don’t hesitate to ask them below.